Double major outage in record time

- Goals

-

- Improving Efficiency

- Increase Power Output

- Reduce Operating Costs

- Sectors

-

- Power generation

- Asset

-

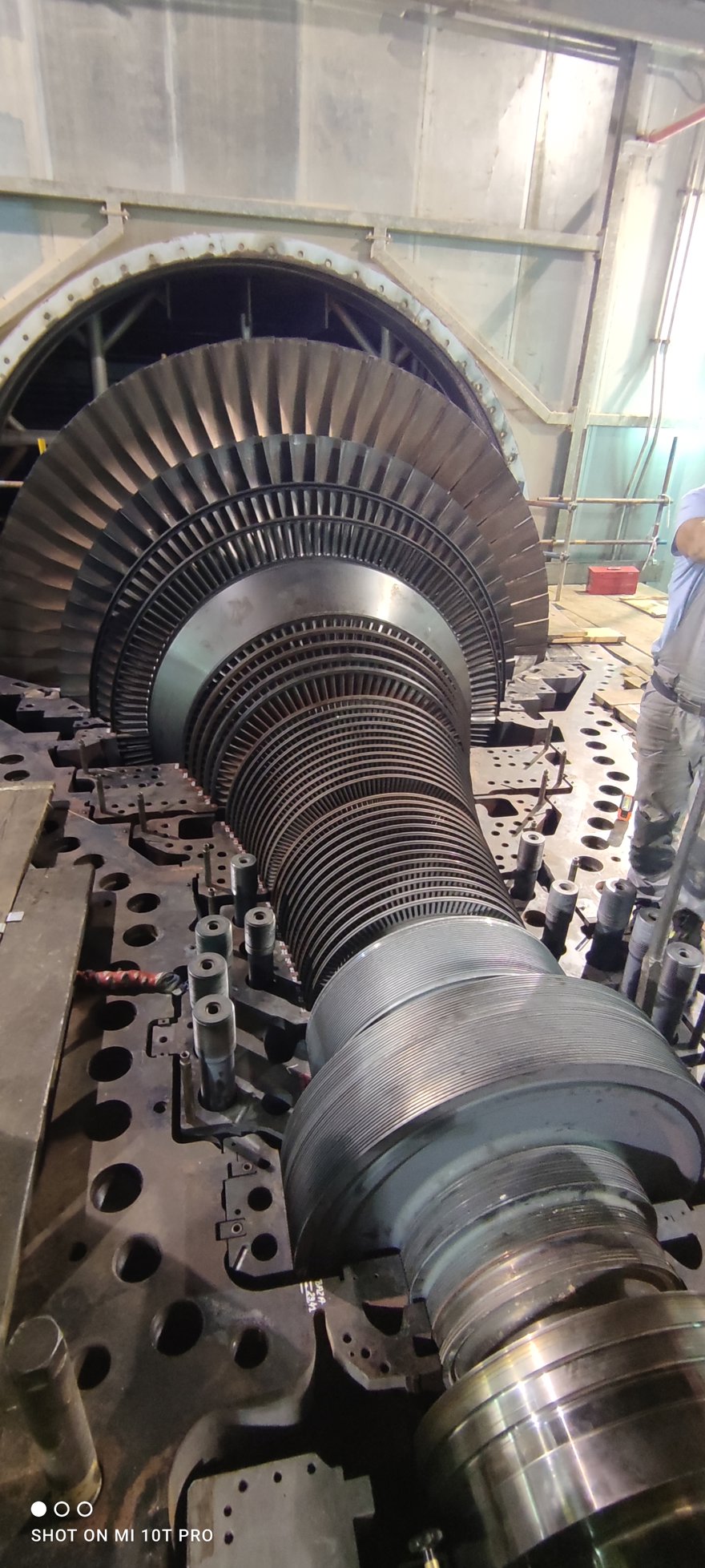

- Steam Turbines

- Generators

- Location

- Balochistan, Pakistan

The Challenge

A race against the clock

Our client needed us to perform not one but two major outages – a steam turbine inspection and generator repair for its Fuji Electric unit – within the tightest of timetables.

To complicate matters further, we had only six weeks to prepare.

Six weeks to arrange the tooling, cranes, grit-blasting material, and local manpower. Six weeks to obtain visas for our steam turbine and generator teams from Wroclaw and Lubliniec in Poland. Six weeks to mobilize the workforce to Uch-II Power Plant’s remote location in the Balochistan Province of Pakistan – 600 km north of Karachi and a six or seven-hour drive from the nearest airport.

Could it all be done?

The Performance

Under Pressure

Ethos faced multiple challenges towards executing this project, navigating strict timelines and client expectations. These challenges included:

A short turnaround time

The job was completed within the specified schedule by adopting 12-hour shifts, operating seven days a week.

Transportation and logistics

Successfully managed the movement of two substantial cranes, one weighing 500 tons and the other 100 tons.

Harsh Weather Conditions

(exceeding 40 °C) – To address the risk posed by high temperatures to personnel, a two-hour break cycle was implemented.

The Impact

The EthosEnergy Solution

We succeeded in carrying out both the steam turbine and generator major outages within the stipulated timeframe. Feedback was very positive, and our client applauded us for the speed with which we had managed to pull everything together in time to start the outage.

Our client should also be applauded. They provided us with fantastic support and cooperation throughout the project, and that teamwork was rewarded with the results that we achieved together.

Following the success of this project, we have been awarded contracts to perform other steam turbine inspections. These have been throughout the Middle East region. We have also had fruitful discussions about performing steam turbine maintenance at several other power plants owned by ENGIE.

Related Case Studies

-

Reduced outage and costs on a D-11 steam turbine

EthosEnergy completed a blade replacement using a patented titanium blade refurbishment process on the L-0 blades of a GE D-11 steam turbine rotor (double flow LP, 300 MW) for 500+ MW Combined Cycle Power Plant for a large utility in the US.

-

Fast resolution for a 10 MW steam turbine forced outage

All systems go for major repairs in the Caribbean

-

Major outages at two of Pakistan’s largest steam turbines

Bringing global expertise, flexibility, and a local approach to steam turbine and generator maintenance services for Lalpir Power and Pakgen Power

Related Services

-

Steam Turbines

Increase reliability and efficiency on your steam turbines. Industry-leading engineered solutions and turnkey support for both planned and unplanned maintenance.

-

Generators

In practice, there is no aspect of a generator repair that we cannot implement: from rewind to upgrade, from repair to overhaul. Clients rely on EthosEnergy to support them with both repair emergencies as well as ongoing maintenance when it comes to industrial generators.