Your partner in Geothermal power

EthosEnergy leads the way in delivering innovative solutions for geothermal power plants, tackling safety and reliability challenges head-on. With over 50 years of experience, we provide industry-leading engineered solutions for the geothermal industry, including steam turbines, generators, and transformers.

We provide custom solutions and act as a single-source provider for your steam turbine and generator needs. Our proven track record boasts numerous successful projects, demonstrating enhanced reliability, performance, and efficiency for geothermal power plants globally.

Sales

Geothermal Power Services

We provide a full range of independent and OEM approved solutions for your turbine, generator and transformer products and services that are specific to the Geothermal Power industry.

-

Steam Turbines

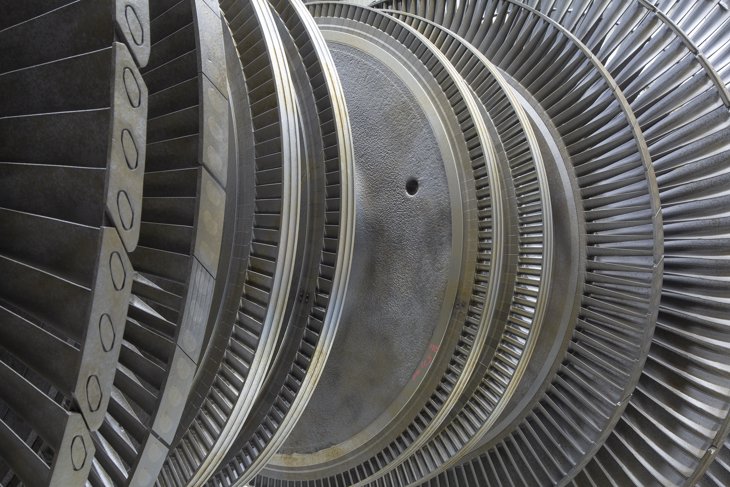

Increasing reliability and efficiency on your steam turbine. Industry-leading engineered solutions and turnkey support for both planned and unplanned maintenance.

-

Generators

We provide an extensive range of generator services ranging from the manufacturing of stators and rotors, to generator windings kits.

-

Transformers

We design and manufacture new grid transformers, autotransformers, Generator step-up (GSU) and other special type transformers, specifically for your power generation requirements.

-

Field Services

Our turbomachinery field services provide 24/7 availability, rapid mobilization and industry-leading safety performance for your power generation facility.

Our experience in Geothermal power

From handling repair emergencies to providing ongoing maintenance for geothermal power plants, EthosEnergy's track record guarantees dependable support. We offer a wide range of capabilities covering steam turbines, generators, and transformers, delivering tailored solutions to address clients' unique requirements and challenges.

Over 900+ steam turbine overhauls, upgrades, and repairs

- Complete steam path inspections

- Rotors, diaphragms, blade rings, casings, valves & seals

- Rapid turnaround on replacement parts

- Weld restoration of gland steam shaft seal areas, diaphragm vanes, seal faces &joint restoration

- Welded repaired or re-rounded casings

- Replacement rotors & diaphragms

- On-site and shop based overhauls

- Advanced rotor welding

- Modern airfoil shapes improve efficiency

- Lower alternating stress & resistant corrosion assisted fatigue cracking

- New 72cr diaphragms with improved moisture removal

- Improved rotor, blade material & coupled blades

- New generators and components

- Diagnostics, testing, and inspections

- Generator assessment programs

- Maintenance and repair

- Rewinds and rebuild

- Upgrades and modernization

- Diagnostic and engineering

- Field and site services

Videos: See inside our steam turbine workshops

Geothermal Steam Turbines

Industry-leading engineered solutions and support for the geothermal power industry. Over 40 years of experience with 900+ steam turbine overhauls, upgrades and repairs.

Download our Geothermal applications brochure to learn more.

Our case studies with real results

Discover the proven projects EthosEnergy has successfully undertaken worldwide, highlighting the significant impact our services have had on our customers in the geothermal sector.

Geothermal Power FAQs

Geothermal power plants must conduct meticulous maintenance on critical rotating equipment, such as steam turbines, to ensure operational efficiency and longevity. Regular visual inspections are crucial to detect any anomalies. Maintenance activities include checking oil levels, ensuring the cleanliness of turbogenerator lube/seal oil skids, and inspecting gearboxes. Additionally, internal inspections of pressure equipment, potentially influenced by regulations, are performed to identify issues like scaling or deposition. Overhauls, which may start annually and extend to longer intervals, are essential to mitigate operational costs and maintain plant availability. The focus on steam cleanliness and the prevention of turbine damage from steamfield design problems is paramount.

Steam turbines are the heart of geothermal power plant operations, playing a pivotal role in converting geothermal energy into electricity. They harness the high-pressure steam produced from the Earth’s heat to drive the turbine blades, which in turn rotate the generator to produce power. The efficiency and reliability of steam turbines directly impact the plant’s operational performance and profitability. Moreover, the design of steam turbines must accommodate the unique characteristics of geothermal steam, which can include corrosive elements and varying pressures. Thus, maintaining steam turbine integrity is essential for the continuous and effective generation of geothermal power.

EthosEnergy provides comprehensive support for geothermal power plants through a variety of services. They offer engineering solutions tailored to the needs of geothermal facilities, including component repair, optimization, and upgrades. For instance, at the Tiwi Geothermal Plant in the Philippines, EthosEnergy performed a geothermal steam turbine retrofit to address the decline in steam from the geothermal reservoir2. They redesigned turbine components to increase efficiency and extend the life of the equipment. EthosEnergy also provides field services with 24/7 availability for rapid mobilization and operations and maintenance services to manage and operate plant’s power, heat, and process steam risk profiles. Their approach aims to reduce operating costs, enhance performance reliability, and support the energy transition towards sustainability.

When a steam turbine is designed, the steam path must pass the required flow at the design steam conditions. The steam path is designed to get the best possible velocity ratio which is the ratio of the wheel velocity divided by the steam jet velocity. When the turbine is operating at part load the steam velocity drops causing a loss in efficiency. There is also a part load effect from the generator as well. The total loss in efficiency can be more than 10% when a steam turbine is operating at 50% load. If long term operation is expected at reduced load, a derate could be a way to regain lost output and at the same time extend the life of the turbine.

Without question, moisture is an issue on geothermal flash plant units. There are mechanical features that can be designed on the outer diameter of the diaphragms that act as “moisture separators” to pull water droplets from the discharge of the blades. EthosEnergy has also been granted a Patent on a system to monitor the casing drains that can become clogged over time.

Yes, in many cases, we have been able to redesign the rotating blades to have integral covers which also has a performance benefit.