Auxiliary and fuel solutions

Cost and quality of fuel can frequently shift, and composition variations can significantly influence emissions and combustor dynamics.

EthosEnergy designs systems that provide operational flexibility to select gas, oil, dual, blended, or alternative fuel solutions.

Sales

Compressor water wash

EthosEnergy has developed gas turbine compressor cleaning solutions that aim to recover lost performance while improving heat rate and unit availability.

This EcoValue™ technology has both offline and online options and uses highly atomized water spray patterns designed to completely enter the compressor core.

The patented and highly atomized EcoValue™ technology is individually configured for each turbine type. This process includes 3D modeling of inlet and nozzle positioning, and Computational Fluid Dynamics (CFD) to study droplet trajectory and evaluate and confirm nozzle positions. EthosEnergy’s equipment can be made ATEX EEXD Zone-1 classed for refineries and other hazardous area applications.

Power augmentation upgrade

Power augmentation technologies provide the optimum balance of increased power output, minimal long-term equipment maintenance costs and maximum equipment reliability.

EthosEnergy provides a fully automated, PLC-controlled skid with a direct injection nozzle arrangement that delivers high reliability and a longer life span.

This direct injection system uses nozzles installed directly in the turbine bell mouth and / or cone section. Direct injection of water into the compressor is designed to incorporate the correct droplet size that is evenly distributed across the compressor throat.

The water injection points are located within the high velocity region which eliminates the concern for concentrated water at the blade root.

Inlet fogging systems use an array of fogging nozzles placed downstream of silencers within the inlet duct.

Through an in-depth analysis of the technology traditionally used in this application, EthosEnergy has engineered a system that mitigates the design faults that involve spray nozzle positioning and over saturation of the airstream associated with most existing systems.

ECOMAX® turbine optimization

Our precision autotuning and combustion optimization platform uses live data so that you can operate on your own terms, even in extreme conditions. Our advanced technology and patented sensor-based algorithm continually monitors and automatically fine-tunes combustion parameters, responding to live metrics to maintain NOx and CO emissions compliance, flame stability and combustion dynamics, while ensuring optimal power output.

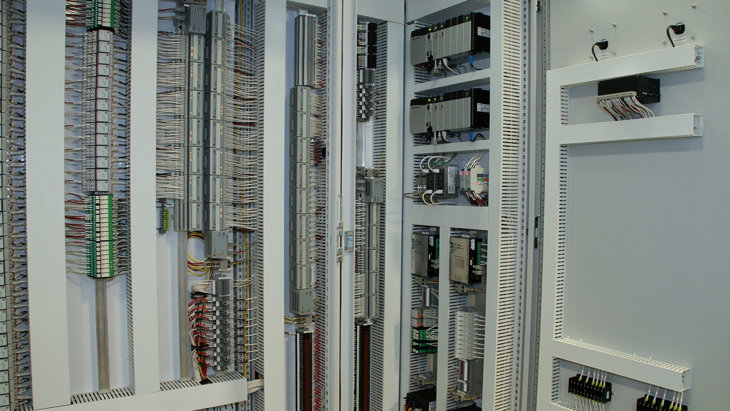

Control system upgrades

Our experienced iCON™ control system upgrades provide increased flexibility, availability and risk reduction to owners and operators of gas and steam turbines.

We maximize our customers’ success by providing a non-proprietary and proven open-architecture solution that allows for the ability to be self-sufficient.

Real results on gas turbines

A broad portfolio of work with real-life examples showing increased reliability, increased output, and industry leading quality.