Dry gas seal system optimization - outboard seal backpressure stabilization

EthosEnergy was contacted by an operator of an offshore booster compressor operated at a depleting gas field, experiencing low leakages and low pressures in the primary vent.

- Goals

-

- Increase Power Output

- Sectors

-

- Oil & Gas

- Asset

-

- Compressors

- Location

Project Overview

EthosEnergy was contacted by an Operator of an Offshore booster compressor operated at a depleting gas field, experiencing low leakages and low pressures in the primary vent.

In order to maintain a stable operating pressure for the primary vent system EthosEnergy advised the implementation of an outboard seal back pressure stabilization system.

This self-regulating system will increase the flow toward the primary vent for normal operating conditions, which will stabilize the seal monitoring during transient conditions. The additional flow will be disabled when the primary vent pressure rises towards alarm and trip levels.

Problem Description

It is known from experience on compressors running at lower suction pressures (< 20 barg) that tandem dry gas seal configurations without secondary seal gas can suffer from low leakages and low pressures in the primary vent.

During operation at lower pressures, the seal leakages are very low, especially for bi-directional modern dry gas seals, and may result in insufficient process gas entering the primary vent to provide a stable operating pressure for the outboard (secondary) dry gas seal and the primary vent pressure control valve.

The EthosEnergy Solution

In order to maintain a stable operating pressure for the primary vent system for this configuration, EthosEnergy advises the implementation of an outboard seal back pressure stabilization system.

This self-regulating system will increase the flow toward the primary vent for normal operating conditions, which will stabilize the seal monitoring during transient conditions. The additional flow will be disabled when the primary vent pressure rises towards alarm and trip levels.

Project Highlights

Seal system problem at depleting gas field

Stabilization of seal back pressure

Full functional seal protection during start-up

As well as optimized outboard seal operating conditions

Solution

Applicable for all compressors equipped with tandem dry gas seals without intermediate labyrinth purge

Required Modifications

- Include check valve in the common primary seal gas supply line

- Include a pressure regulator (fail closed) with accompanying pressure indicator in the common supply line.

- Include check valve and needle valve with locking device in the individual supply lines

- Modify parts of existing piping to include tie-in points

- Changes to the controls to force open the flare backpressure control valve during a blow down of the compressor at a sealing pressure of 0.5 bar above the set pressure

Applicable Area

All compressors equipped with Back Pressure Stabilization Problems, such as with tandem dry gas seals without intermediate labyrinth purge. Amongst other areas of application, this problem area is frequently identified with compressors installed on depleting gas fields offshore.

Key Results

The key results of the project include increased compressor reliability and availability, reduced production losses and stable seal gas consumption.

Find out more

-

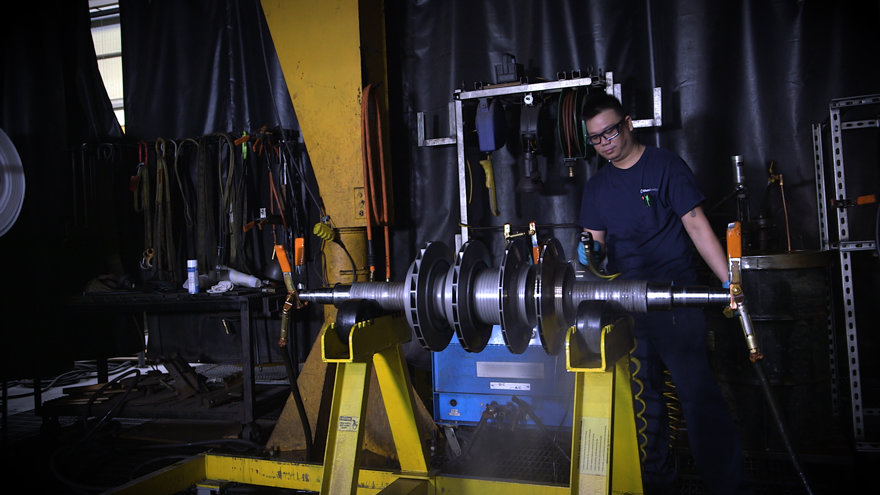

Compressors

We can inspect, repair, reverse-engineer and re-build centrifugal, axial, and integrally geared compressors from any OEM.

-

Heavy Duty Gas Turbines

EthosEnergy is the leading independent provider of heavy-duty gas turbine services, including outages, inspections, repairs, overhauls, rotor manufacturing, and life extension. We specialize in GE frames (3, 5, 6B, 6FA, 7E/EA, 7FA, 9E, 9FA), Siemens Energy SGT600 (GT10), and OEM support for Fiat Avio and mature Westinghouse turbines, maximizing availability, reducing risk, and controlling lifecycle costs.