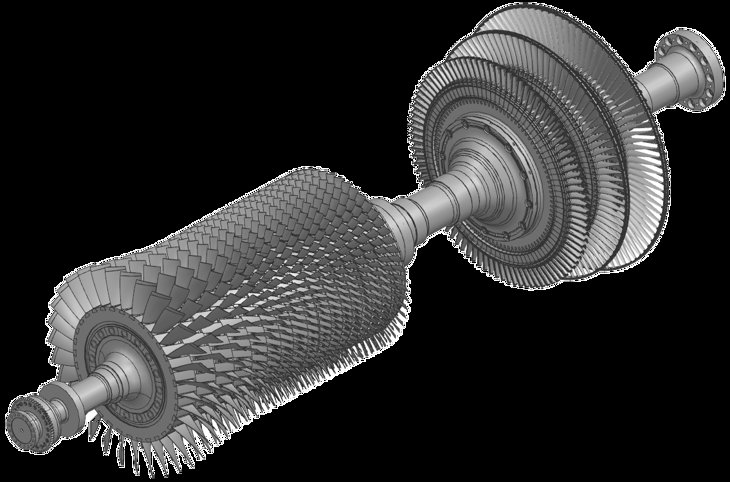

Lassen Sie Ihren Rotor länger laufen

Wenn es um die Verlängerung der Rotorlebensdauer von GE-Gasturbinen geht, gibt es mehr Optionen, als Sie vielleicht denken. Es gibt Optionen, die über den Kauf eines neuen Rotors vom Erstausrüster, den Umstieg auf eine neue Technologie oder den Austausch Ihres Rotors durch riskante gebrauchte und Graumarktoptionen hinausgehen.

Sie benötigen einen vertrauenswürdigen Partner, um diese Optionen zu nutzen. Wir haben einen doppelten Vorteil: Wir können sowohl die Leistungsfähigkeit/Qualität/Standards eines OEM (als OEM für Fiat- und Mature Westinghouse-Gasturbinen) als auch die kommerzielle Flexibilität eines ISP bieten.

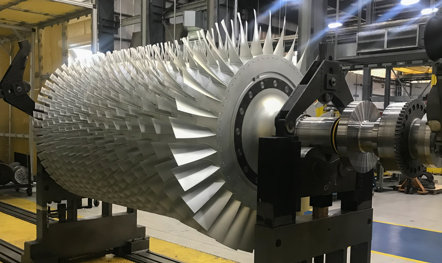

In den letzten 15 Jahren haben wir uns auf den Rotormarkt konzentriert und umfangreiche Erfahrungen in der Entwicklung, Reparatur und Herstellung von Komponenten für Einheiten der B-, E- und F-Klasse gesammelt.

Dies bedeutet, dass wir sowohl den Rotoraustausch als auch die Lebensdauerverlängerung vorhandener Rotoren anbieten können; dies schließt auch neue Rotoren ein, die in unserem Unternehmen hergestellt werden.

Vertrieb

Vorteile einer Rotorlebensdauerverlängerung

Wenn Sie bei Ihrer aktuellen Technologie bleiben und sich für eine Verlängerung der Rotorlebensdauer entscheiden, anstatt den Rahmentyp oder die Technologie zu ändern, bietet das erhebliche Vorteile. Dabei sind insbesondere die Kosteneffizienz und die CO2-freundliche Entscheidung zur Wiederverwendung statt zur Neuherstellung von Vorteil.

EthosEnergy ist die einzige Nicht-OEM-Rotoroption für die B-/E-/F-Klasse, die OEM-Technologie und -Materialien verwendet. Zu den wichtigsten Vorteilen gehören:

- Vollständig kompatibel und austauschbar, um Ausfallzeiten zu minimieren

- Verbessertes Design bei neu hergestellten Rotoren, um bekannte Schwächen des ursprünglichen Designs zu beheben

- Minimale Bearbeitungszeit – keine neuen Genehmigungen erforderlich

- CO2-freundlich (ESG-freundlich) durch Wiederverwendung vorhandener Vermögenswerte statt Neuanschaffung

- Flexible, maßgeschneiderte Lösung von einem Partner, der Sie durch den Rotoraustausch führt

Lebensdauerbewertung (LTA)

- TIL 1576 ermöglicht eine mögliche einmalige Verlängerung über die FFH/FFS-Grenzen hinaus auf Grundlage der Ergebnisse einer LTA. Die qualifizierten Handwerker und Ingenieure von EthosEnergy können die LTA durchführen und die mögliche Lebensdauerverlängerung auf Grundlage der Ergebnisse bestimmen.

Zustandsabhängige Lebensverlängerung (CBLE)

- Unsere qualifizierten Ingenieure führen eine detaillierte Bewertung des Rotorzustands, der damit verbundenen Risiken und Empfehlungen für den Komponentenaustausch mit einer möglichen Erweiterung um 50.000 bis 200.000 FFH und 2.500 FFS durch.

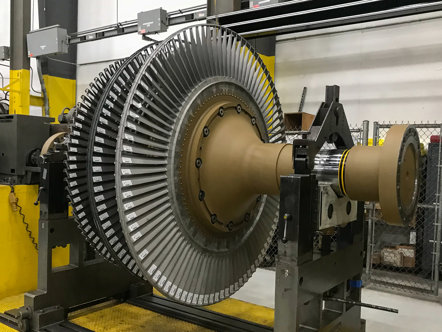

Neuer Rotor

- Unsere Produktionsstätte im italienischen Turin kann das verbesserte Rotordesign von EthosEnergy herstellen, das mit Ihrem aktuellen Rotor austauschbar ist.

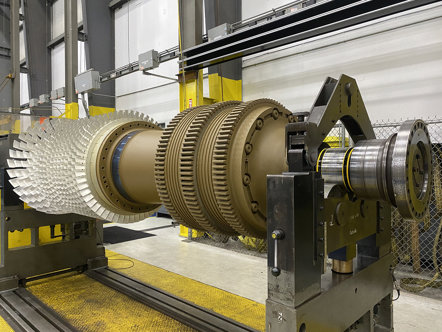

Phoenix Rotor™

- Ein Hybridrotor mit neuen und Certified Previously Operated (CPO)™-Komponenten, die für die gleiche Lebensdauer wie ein neuer Rotor zertifiziert sind. Für die EthosEnergy Phoenix Rotor™-Kompressor- und Turbinenrotorscheiben werden bewährte OEM-Designs und -Materialien verwendet.

Zertifizierte Voroperierte (CPO)™

- Ein Rotor mit bekannter Herkunft, der in einem unserer Kompetenzzentren gründlich geprüft und getestet wurde. Zertifiziert für eine mögliche Lebensdauer von bis zu 150.000 FFH und 2.500 FFS.

Überholungen von Rotoren

Kostenloser Leitfaden zur Verlängerung der Rotorlebensdauer von GE

In unserem eGuide behandeln wir:

1. die Auswirkungen von TIL 1576 auf die Verlängerung der Lebensdauer von GE-Gasturbinenrotoren;

2. was Sie tun müssen, um das TIL einzuhalten und Ihr Risiko zu verringern;

3. wie Sie zu einer genauen Einschätzung der verbleibenden Lebensdauer Ihres Rotors gelangen; und

4. Ihre Möglichkeiten zur Verlängerung der Lebensdauer von Gasturbinenrotoren

...und vieles mehr!

End-of-Life-Lösungen

F-Klasse: Neue Rotoroptionen erschließen

Erfahren Sie, wie wir bewährte Reverse-Engineering-Methoden zur Herstellung von Ersatzrotoren für Frame 7F und 9F eingesetzt haben. Ihr Rotor wird durch eine verbesserte, aber vollständig kompatible und austauschbare Version ersetzt, um maximale Zuverlässigkeit und Leistung zu gewährleisten. Unsere Rotoren sind durch eine Garantie abgedeckt und technisch und kommerziell auf Ihre Bedürfnisse zugeschnitten.

Rotorlösungen der B-/E-Klasse

Wir haben eine Reihe zuverlässiger Lösungen zur Lebensdauerverlängerung für die Einheiten der Baugrößen 6B, 7E, 7EA und 9E entwickelt, die es Ihnen ermöglichen, Ihre aktuelle Technologie beizubehalten. Erfahren Sie mehr, indem Sie unten unser Produktblatt herunterladen.

Ecoview™ Lebenszyklusanalyse

Wir stellen die branchenweit erste LCA-Lösung für Gasturbinenrotoren von EthosEnergy vor, die es Ihnen ermöglicht, Ihre Turbine aus einer nachhaltigen Perspektive zu betrachten. Unsere Lebenszyklusanalyse verschafft Ihnen die Transparenz, die Sie für fundierte Entscheidungen hinsichtlich der Ausrüstung benötigen, um die Anforderungen der Energiewende zu erfüllen und CO2-Emissionsziele sowie ESG-Ziele einzuhalten. Vertrauen Sie auf Ihre Nachhaltigkeitsberichterstattung und steigern Sie Ihre ESG-Glaubwürdigkeit. Unser neues CO2-Überwachungstool wurde in Zusammenarbeit mit führenden Wissenschaftlern entwickelt und bietet umfassende Einblicke in die Umwelt in jeder Phase des Lebenszyklus. Es quantifiziert klar und deutlich die CO2- und finanziellen Einsparungen, die Sie durch die Rotor Lifetime Extension (LTE) im Vergleich zum Neukauf erzielen können. | Wissenschaftliche Studien haben gezeigt, dass sich durch die Verlängerung der Rotorlebensdauer (LTE) CO2-Emissionen einsparen und ein abiotischer Abbau von bis zu 40 % erreichen lässt.

Mit der branchenweit ersten EDP-Zertifizierung für Gasturbinenrotoren können Sie Ihre Ökobilanzergebnisse bald für die nächsten fünf Jahre verifizieren und zertifizieren. So weisen Sie Ihre ESG-Konformität nach und verschaffen sich mit dem Umweltzeichen Typ III (ISO 14025) einen Wettbewerbsvorteil. |

Fallstudien zur Verlängerung der Rotorlebensdauer

Bewährte Lösungen für Gasturbinen

Wir tun, was wir sagen. Sehen Sie sich Beispiele an, wie wir mit unseren Kunden zusammengearbeitet haben, um echte Ergebnisse zu erzielen, und entdecken Sie, was wir für Sie tun können.